It makes no sense to prove the need to have a supply of water on the site for irrigation. If something happens to the irrigation system, your flowers and vegetables will turn into hay on the hot days of July. When my old steel tank was leaking, there was a need to urgently find a replacement. Assessing the harsh reality, I decided to make a structure that would decorate the site, be durable, inexpensive, and did not attract "guests". Having gone through different variants, I chose, as it seems to me, the most successful one: to make the base of the container from galvanized steel sheets, "dressing" it in concrete.

Sheets of steel with dimensions 1000 x 2000 mm are connected to each other with a ring. In order for the container to have a volume of 1 m3, I made a ring of 2 sheets. The seam before "pressing" was treated with a sealant for plumbing work, like all subsequent seams. The result is a springy flexible ring that can be shaped into any shape.

For a capacity of 1 m3, it is enough to make a foundation with a thickness of 120-150 mm, laying it on a crushed stone pillow. The area of the foundation must be larger than the area of the container. Having chosen a place, he took out the soil to a depth of 200 mm, covered the hole with rubble and sand, tamped it down, spilled abundantly with water, prepared concrete. He laid half of it on rubble, on it - reinforcement made of steel rods and pipes, and poured the rest of the concrete onto these structures. Water should be added to concrete so much that it does not spread, but resembles gingerbread dough. In this case, no formwork is required, and the edge of the foundation will look like stone "influxes". The concrete is not poured into place, but is laid with a shovel and tamped, you can use a wooden mallet.

The next operation is installation metal base... The laid concrete is carefully leveled. To do this, he poured a cement-sand mixture (1: 3) of the consistency of liquid sour cream onto the foundation and dispersed it with an even rail. After letting the leveling layer dry out (lose fluidity), put a sheet of galvanized steel on it and pressed it with bricks. This is the bottom of the future container. Previously, the sheet was cut so that it corresponded to the configuration of the container and protruded along the perimeter by 20 ~ 30 mm. In this state, the foundation was left to dry for a day.

A day later, I installed a galvanized steel ring on the bottom, having previously made 2 holes in it: one at the bottom at the very edge for the drain pipe, the other 300-400 mm above the edge for taking clean water. If all the previous work was done carefully, then gaps in some places of no more than 5 mm are permissible between the wall and the bottom - they will not affect the quality of the container. Having installed the wall and fixing it with bricks, he overlaid the outside of the joint between the wall and the bottom with a steep but plastic "dough" made of a mixture of cement and sand (1: 1) with the addition of PVA glue (1 tbsp. Spoon of glue for 0.5 l of water). After drying the "dough" for 24 hours, he removed the bricks and completed the joint filling in the places occupied by the bricks. Having completed the joint, I installed a tube (aluminum, stainless steel, plastic) in the hole in the wall at the bottom, carefully overlaid it with a cement mortar. Then he proceeded to the construction of a concrete wall.

The concrete for the wall is prepared in the same way as for the foundation. He did the work like this: he took a portion of concrete with a trowel, put it against the steel wall (it played the role of one-sided formwork), tamped it slightly so that the concrete spreads out and presses tightly against the wall. And so along the entire perimeter. When laying concrete, one must strive to ensure that the wall thickness is not the same. Then a surface is formed that resembles the natural texture of the stone. At the same time, you can show your abilities as a sculptor, guided by a sense of beauty and harmony.

When constructing the wall, do not forget that a drain pipe should go out at the bottom, and at a height of 200-300 mm from the bottom, another threaded pipe for a valve must be installed into the wall in order to take clean water... In order to prevent the steel base from deforming during the laying process, it is advisable to lay the bricks inside the container from the bricks, which do not allow the wall to "go" inside under the pressure of concrete.

Completing the laying, you need to make a small influx into the container on the edge of the steel base so that it does not peel off the concrete.

The last stage is finishing. Various options are possible with the use of ceramics, bottle glass, natural stone, etc. I chose a simple option: the entire surface of the container is smeared with a cement-sand mortar (1: 1) and treated with a wet broom. Grey colour cement looks good in the greenery of the garden.

Such a container has many advantages, it is quite cheap, but there is only one drawback: it cannot be moved. Therefore, the place must be chosen carefully, remembering that a capital structure is being built.

Installing a water tank in a bath opens up a number of amenities and advantages to the owner. Firstly, it becomes possible to prepare hot water during the heating of the furnace, which allows saving energy resources and spending them as expediently as possible. Secondly, the use of such a unit in most cases makes it possible to abandon the installation of an electric water heater, which also benefits the budget allocated for the arrangement of the bath.

There are several basic requirements for water tanks: they must be roomy, durable, warm up in the shortest possible time and retain heat for as long as the needs of the steam room visitors dictate. Among the options available to the ordinary user, products made of stainless steel meet the listed criteria to the greatest extent.

Scheme - an example of installing a remote water tank

The modern market offers a wide range of water tanks made of cast iron, stainless steel and enamelled material. As practice shows, it is stainless steel that is most popular among bathhouse owners, which is due to a competent and acceptable ratio of operational and technical characteristics and cost indicators.

Stainless steel is characterized by excellent thermal conductivity, tolerates temperature fluctuations normally and objectively lasts longer than various ferrous metals.

Here a natural question arises: which of the existing brands of stainless steel is better suited for the manufacture of the container in question, intended for operation in a bath? Firstly, it is 08X17 (430), and secondly, 8-12X18H10 (304). The mentioned materials, among other things, are used for the manufacture of tableware and are characterized by high resistance to impact high temperatures are completely hygienic, do not rust or deform during use. In addition, such materials are unpretentious and extremely easy to maintain.

In summary, there are 3 main advantages of stainless steel water tanks:

- products do not require additional protection against high air humidity and normally tolerate operation in conditions typical for a steam room;

- stainless steel has high thermal conductivity, which makes it possible to receive hot water in the shortest possible time;

- stainless steel tanks do not deform due to sudden temperature changes, or these deformations are insignificant.

Stainless steel sheet prices

stainless steel sheets

Design options for water tanks for a bath

Water tanks designed for use in a bath can have a different design. There are 3 main options: a built-in tank, a remote tank and a unit mounted on a pipe. You can see the features of each type of construction in the following table.

Table. Stainless steel water tank structures

| Construction type | Description |

|---|---|

| Installation of representatives of this category is carried out during the construction of a sauna stove, as a result of which the stove and the tank become a single structure. The heating of water in a built-in stainless steel tank is carried out by the forces of fire, due to which the efficiency of the water tank itself is kept at a rather impressive level. The key disadvantage of this design is the fact that a significant part of the heat is spent on heating the water in the tank, as a result of which the heat transfer directly from the sauna stove drops noticeably. Helpful note! Much easier to manufacture and use is the telescopic / hinged tank mounted on top of the heater. |

|

| A more convenient and practical option compared to the previous model, especially if the tank is designed and installed for permanent use. If desired, a ready-made stainless steel water tank can be installed in the washing room of the bath, connecting it with a pipe system with an oven heat exchanger. Optimal material pipe making - copper or brass. The only significant drawback of the external water tank is the likelihood of getting a burn in case of careless handling - the situation is especially relevant if children go to the bathhouse. |

|

| An on-pipe water tank can be installed either directly above the sauna stove, or in the attic space. In such structures, water is heated in the shortest possible time. At the same time, the heat transfer rates of the furnace unit do not decrease. The undoubted advantage of installing a water tank in the attic is the ability to "unload" the steam room, excluding the container from its environment and providing more free space. |

The table does not include another possible option for installing the tank - on the side of the stove.

Oven with side tank - photo

Oven with side tank - photo

The method is neglected for the simple reason that it is the worst. Water in such a tank will boil very quickly. If the vaping process is delayed, the constantly boiling water will make the atmosphere in the steam room simply unbearable. And with the maintenance of such a tank, there are continuous inconveniences: in order to save space, the container is made high, but very narrow.

Having dealt with the features of stainless steel water tanks and choosing the most acceptable design option, it remains only to determine the optimal volume of the container, after which you can proceed directly to the stage of its manufacture.

When choosing the required volume of a stainless steel water tank, you must first of all focus on the planned number of visitors who will simultaneously go to the bath. For example, if the steam room is not able, due to its physical dimensions, to accommodate more than 2-3 people, you can safely put a tank of 50-80 liters, at the rate of 25-30 liters of water for each bath attendant.

Bucks are different sizes- choose the right one

Using the above recommendation, you can calculate the required volume of the water tank, taking into account the attendance of the equipped bath. For greater convenience, it is recommended to add at least 10-20 liters on top of the calculated value - each person's needs and ideas about comfortable washing are different.

DIY stainless steel water tank

Most of the factory models of water tanks are made of 1 mm thick stainless steel. For self-made it is recommended to use thicker sheets - about 1.2-1.8 mm (a specific indicator is selected in accordance with the volume of the container). The costs of manufacturing the structure in this case will be higher, but you long years you do not have to think about the need for repair, painting, coating with various special compounds and other similar maintenance of the tank.

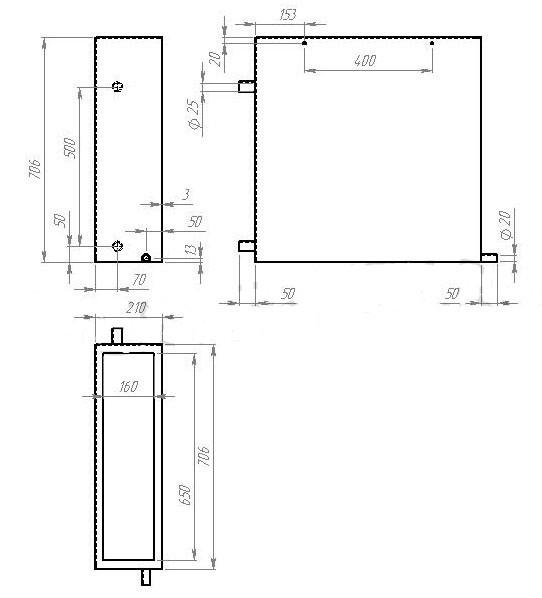

As an example, you can use the following drawing - this is the simplest one for self assembly and one of the most popular design options.

The dimensions can be changed proportionally in accordance with the required volume of the container. The volume is calculated using a standard formula, i.e. the indicators of the length, width and height of the product are sequentially multiplied. For example, the volume of the container presented as an example will be about 25 liters.

Helpful advice! An even simpler version of a water tank is a product made from a piece of seamless stainless pipe. By giving preference to such a solution, you get a number of advantages. Firstly, you do not have to waste time and effort on cutting sheet metal, calculating allowances, stocks and other points, i.e. the likelihood of errors is reduced to a minimum. Secondly, the manufacture of a water tank for water from a pipe requires the use of welding in a minimum amount.

Stainless steel pipes with a diameter of up to 1020 mm and even more are available for sale, which allows you to easily purchase a product for making a container of the required volume without any problems. To determine the volume of the cylinder (namely, this is the shape that the storage tank will have in total), use the following formula.

Helpful note! If you wish, no one will forbid you to make a tank from a profiled stainless pipe, and then the container will have a rectangular shape.

The further procedure for the independent manufacture of a water tank will be considered precisely on the example of using a pipe segment as a workpiece.

Pipe - billet

Important! If an on-tube water tank is planned to be installed, it is better to use a shorter but wider workpiece for its manufacture so that the flue pipe can be passed through the inner cavity of the tank. It will look something like this.

The procedure for making a water tank from a pipe is presented in the following table.

Table. Making a water tank for a bath

| Stage of work | Description |

|---|---|

| Previously, the formula for calculating the volume of a cylinder was given. With its help we find the required height of the water tank. For example, we want to get a tank with a volume of 30 liters and we use a pipe with a diameter of 1020 mm for its manufacture. Using simple arithmetic manipulations at the 5th grade level, we transform the formula into the following form: H = 30 / (3.14 * 0.512) = 37 cm - this is the length of the pipe cut to obtain a water tank of the specified volume. To cut off a piece of pipe, we use a grinder. For working with stainless steel, discs with a thickness of 1 mm and a diameter of 11.5 or 12.5 cm are suitable. |

|

| So that the finished water tank has beautiful view, it is necessary to process the cutting areas accordingly. In the future, similar actions will be performed when boring holes for connecting pipes with valves. The most convenient tool that allows you to quickly and efficiently cope with the solution of the above tasks is a hand drill. Such attachments are equipped with a variety of abrasive nozzles that allow you to achieve the maximum quality of processing of a particular material. In the absence of a manual drill, the seams will have to be tidied up with improvised means: a file, sandpaper and the like, which is definitely a longer and more laborious activity. |

|

| In this step, we need a stainless steel sheet. The lid and especially the bottom are recommended to be made of a material that has a more impressive thickness in comparison with the walls of the pipe chosen for the manufacture of the body. The work is carried out in several stages: - on a sheet of stainless steel, a circle is drawn along the diameter of the holes that it will close. You can just put the pipe on a sheet of metal and draw a circle by tracing the product along the contour; - 2 blanks are cut in accordance with the marking. For cutting and subsequent grinding of the edges, you can use the previously mentioned grinder and hand drill. If an on-pipe method of installing a water tank is assumed, at the same stage, holes can be prepared in the bottom and lid along the diameter of the chimney (preferably 1 mm larger so that the chimney can pass through them, in the future the gap will be leveled by welding). Also at this stage, you can prepare holes for further connection of branch pipes with taps if they are to be mounted in the bottom (it is important for outboard structures installed away from the furnace, in the case of above-furnace / built-in and on-tube tanks, it is more expedient to cut the branch pipes into the wall of the tank body). In more detail, the nuances of drilling and welding stainless steel will be discussed in the relevant sections of the instructions. |

|

| The photo shows a profiled pipe, but the welding process for this case and working with a round workpiece remains the same. Products made from the material in question can be connected in different ways: - by soldering using lead-free or high-temperature solders; - manual or automatic welding (in the case of stainless steel, work is carried out exclusively in a shielding gas environment). The most preferable is the second option, the easiest to learn - manual arc welding. Argon is used as a shielding gas. Welding is carried out using a non-consumable electrode for working with stainless steel. In the international classification, machines designed for such welding are marked with the abbreviation TIG. When buying or renting a welding machine, do not forget to purchase / rent an argon cylinder and a reducer. The function of the latter is to reduce the pressure of the shielding gas at the outlet. The seams should be as neat and uniform as possible. After completing them, it is recommended to clean them. Recommendations for a suitable tool for this have been given earlier. Helpful advice! If desired, the tank lid can not be welded on, but attached with bolts and ears, or simply made removable. The option is relevant for cases when water will be added by the user manually, and not supplied through a water supply. The container is ready. We proceed to the preparation of the holes for further insertion of the branch pipes. |

|

| The structures under consideration are equipped with two branch pipes with valves. Cold water is traditionally fed into the container through the upper branch pipe, and the heated liquid goes to the consumer through the lower branch pipe. The diameters of the plumbing pipes correspond to the diameters of the water pipes used in conjunction with them. The most commonly used pipes are ½ or 1 inch. An ordinary one is suitable for drilling stainless steel electric drill... The main thing is that the work is carried out at low speeds - no more than 100 rpm. In a drill with an electronic governor, setting the required mode is not a problem. If there is no such regulator, you just need to activate the start button with short presses - within a second the instrument will not have time to accelerate to operating power. The holes are best made with a P18 drill. Even more convenient option- special stepped drill (shown in the picture). This tool does not rip up the edges of the hole, so it gets a perfectly round shape. Along with this, for drilling holes with a diameter of more than 14 mm, it is more convenient to use special nozzles - the so-called. "Crowns". |

|

| The presented diameters of such crowns correspond to both inch and metric gradations of sanitary pipes. With the appropriate drill bits, you can also prepare holes in the bottom and lid of the tank if it is intended to be installed on-pipe. |

|

| Nozzles with taps to shut off the water flow are available on the market. In combination with a stainless steel tank, it is preferable to use components made of the same material. In order not to waste extra time on arranging the threads, the pipes are simply welded to the previously prepared holes. Recommendations for tools and welding modes remain the same. After installing the water tank in accordance with the selected scheme (will be discussed later), they are connected to the nozzles water pipes(previously noted that it is best to use products made of copper or brass) of a suitable diameter. The connection of the branch pipe to the pipe is made in any suitable way, for example, using a threaded adapter. |

So, the water tank is ready, and even the pipes for tapping pipes are already installed. It remains only to connect the finished device for its subsequent use for its intended purpose.

The procedure for connecting a stainless steel water tank

Important notes before starting work

It was previously noted that the most common options for mounting a tank are: inside the oven, away from it and on the chimney. We propose to replace the first option with a method in which the tank is installed above the stove heater. This method is easier to implement, while you can resort to using it, even if the stove has already been built - suddenly you thought at first that you would not need such a heater, and after studying the material presented, you understood all the advantages of its use and wanted to install it in your bath ...

Important! It will be possible to implement the mentioned replacement only in the case of a collapsible chimney. The proposed method involves the combined installation of the tank - it will be simultaneously placed above the stones and around the chimney, which will make the water heating efficiency as high as possible. Otherwise, you will either have to give preference to the built-in tank model (if the furnace is just being built), or install the unit at a distance from the stove.

If the stove is brick, the preparation of the place for the tank and its direct installation are carried out during the laying process (the specific stage depends on the chosen design of the stove and the size of the furnace, most often it is row 10). When laying a row, an opening is left to accommodate the tank. The size of the opening should be several millimeters larger than the dimensions of the structure to be installed to compensate for thermal expansion.

The diagram shows an opening for installing a tank

Note! In the intervals between the marked brick quarters, pipes are laid, the presence of which will increase the heating efficiency - these are the structural features of this particular furnace unit, these pipes may be absent in your chosen project.

A stove with a tank installed looks like this.

A plumbing tap is cut into the tank wall from below. It is assumed that the user will draw hot water directly from the steam room. If desired, the design can be improved by cutting in the previously mentioned branch pipe instead of the tap, connecting the water pipe to it and bringing it into the washing room.

When the masonry is brought to the upper edge of the tank, 2 metal strips are laid on it, the presence of which will allow you to safely block the storage tank with a brick.

In the case of metal bath stoves, the water tank is welded over the firebox (recommendations for welding were given earlier). As a result, the container is heated by the forces of the flame, which ensures the fastest possible preparation of water. The construction looks something like this.

Important! If preference is given to a built-in tank structure, metal with a thickness of more than 1 mm should be used for its manufacture and, at the same time, ensure that the quality of the welds is as high as possible. Otherwise, the tank will either quickly burn out, or it will leak through poor-quality seams.

Helpful advice! In case of brick oven you can go a simpler way by placing the water tank on the furnace body above the firebox. The design looks something like this.

Installing the water tank over the stove

This method, as noted, involves the combination of options for installing the tank above the stove and on the chimney. The distance between the stove and the bottom of the tank is usually maintained in the range of 20-35 cm with the possibility of changing in both directions: the smaller this indicator, the faster the water will heat up, but the tank will last less, and vice versa.

Provide detailed step by step instructions does not make sense - you already have all the necessary knowledge. Previously, it was described how to prepare holes in the bottom and lid of the tank for passing the chimney through them. Do it.

Next, you need to pass an element of the smoke exhaust system through the inner cavity of the tank and connect the pipe to the tank at the entry and exit points (in the bottom and lid) by welding. You also know how to do this.

Stainless steel water tanks are relatively lightweight (for example, cast iron is much heavier and a tank made of it would require fixing to the ceiling using chains or another suitable method) and do not require additional fastening. Further installation of the chimney is carried out according to the standard scheme, depending on the selected type of construction.

Ideally, the finished system will look like this.

No connections or taps are visible in the image shown as an example. The next design is not so beautiful in appearance, but the connection of the water outlet is clearly demonstrated here.

With regard to filing cold water, it can be organized in several ways, depending on the characteristics of a particular situation:

- the tank is filled manually;

- water is supplied from a well / well;

- water supply is carried out from a centralized water supply system.

We will not consider in detail each of the listed options, since these are topics for separate bulky instructions.

Installing a remote water tank

The arrangement of such a system is also not overly complex. The only thing is that the scheme is supplemented by a new device - a heat exchanger. It can be built-in or external. For self-production, it is better to choose the second option - it is more convenient and easy to implement.

A schematic of a system with a remote water tank is shown in the following image.

Here we can see that an external heat exchanger is installed on the chimney. The water in the heat exchanger is heated by the heat of the flue gases transmitted through the pipe walls. If there is an open stove under the heat exchanger, additional heating will be carried out by the heat of the hot stones.

Warming up in the heat exchanger, the water goes into the external tank, from there, cooling down, back to the heat exchanger. The circulation of water will be provided by the created slopes and the pressure difference in the container with hot and cooled liquid.

Remote tank with hot water for 60 l

You can make a heat exchanger yourself. In fact, this is the same water tank, the instructions for the manufacture of which you have already studied, only of a smaller volume (usually up to 5 liters). The installation of the heat exchanger is carried out in the same way as the tank in the previous instructions (on the chimney).

Register - heat exchanger for sauna stoves

Heat exchanger prices

heat exchanger

You already know how to make the necessary holes, install pipes, taps and pipes. Where to do it - see the diagram. It remains only to prepare all the required elements and assemble them into a single system, maintaining the required distances and slopes in accordance with the above scheme.

In this example, a remote water tank is installed in the washroom and is equipped with a standard plumbing valve to drain the water. The pipes, like the aforementioned crane, are cut into the bottom of the tank. Holes for routing pipes through the baffle can be made using a suitable tool such as a hammer drill.

In accordance with the current provisions of the current standards, cold and hot water supply pipelines, if they are laid through a partition, must be laid through a sleeve. The diameter of the latter is selected so as to exceed the outer diameter of the pipe to be installed by 0.5-1 cm. A non-combustible soft material is used to seal the gap between the sleeve and the pipe, so that, as a result, it is possible to move the pipe along the longitudinal axis in the event of thermal expansion. This is shown schematically in the following image.

The gaps in the partition can be masked in any suitable way, for example, by filling it with the mentioned soft non-combustible material and covering it with an external decoration element (clapboard, etc.).

It remains only to figure out how to fix the water tank on the wall. The easiest option is to install on metal corners, the capacity of which would be sufficient to support the weight of the water tank.

Mounting is carried out as follows. Having attached the corners to the wall, you put marks on the surface, drill holes according to the marks and mount dowels in them. Next, screw the corners to the wall using bolts 8-10 cm long and 1-1.2 cm in diameter.

You can install your water tank on the corners. The method is extremely simple to implement, but not the most reliable (they made a mistake when choosing the corners - they caved in - the tank fell), and it is objectively suitable only for rectangular structures of a small volume. The fastening method used when installing domestic water heaters is more reliable. To implement it, you will have to work with welding machine... You already have all the necessary knowledge, so no additional explanations are required. The procedure is as follows:

- a strip of metal is cut off (the same stainless steel is suitable) with a thickness of 1.5-2 mm, a width of 5-10 cm and a length so that it protrudes beyond the side walls of the heater by a few centimeters on each side;

- holes are drilled in the strip along the diameter of the fastening bolts (you will understand by looking at the image below);

- the finished fixing strip is welded to the rear wall of the tank.

Further steps are similar to the previous instructions, with the only difference that the water tank is not installed on the corners, but is attached to the wall through them by means of a welded bar. It looks like this.

The tank is installed. You can test and, if everything is normal (there are no leaks, excessive heating and other unfavorable phenomena), take the structure into permanent operation.

If desired, the system can be improved almost indefinitely, completing with various automation, measuring instruments, etc. The possibility of installing additional wiring in order to connect the tank to the shower cabin in the washing room is not excluded - this will allow you to wash with maximum comfort. An example of the implementation of such an idea is presented in the following image.

Helpful advice! Install the tank in such a way that it is as far away as possible from both the sauna stove and the hot water intake.

Having sufficiently mastered the art of welding stainless steel, if you wish, you can make a tank not from a pipe, but from sheet material- this is more responsible work in comparison with the considered option. An example of its implementation is detailed in the attached video.

Happy work!

Video - How to make a stainless steel water tank for a bath

One of the most unpleasant household problems is the lack of water in the tap. It is easy to survive the absence of light or gas, but water is an indispensable component of human life, and when there is no or little, problems begin. You can keep several containers of water constantly in the house, for example, plastic bottles, but it is much more practical to determine which storage tank is needed for water supply and a system diagram for a private house, so as not to lose comfort and continue to use household appliances and a sink with a bathtub, as in what has not happened.

Why you need it and how to use it

If, for some reason, the pump in the autonomous water supply system does not work, or there is no pressure in the centralized city water supply, then it can be fed into the sink or toilet bowl from a previously recruited reserve tank. Simply put, it is best to always have a supply of drinking water in the house and use it in an emergency.

For the convenience of using the reserve water supply, the storage tank must be integrated into the water supply system so that it is either automatically used in the absence of an external pressure, or it can be activated by simply turning the valve.

There are many variations on how to install and connect a storage tank, depending on the type of water source, the possible location of the tank and even the layout of the house. It is enough to choose suitable option and decide on the type of the storage tank itself.

Types

The storage tank can be a container with a sufficient internal volume, made of a material that is resistant to corrosion and safe for storing drinking water. The following materials are used:

- polyvinyl chloride;

- cross-linked polyethylene of high or low pressure;

- polypropylene;

- stainless steel;

- steel coated with waterproof varnishes and ceramic coatings.

Although galvanized steel is corrosion resistant and waterproof, over time, the protective layer of zinc can become thinner, especially at the joints and welds.

By design, they are distinguished:

- open containers that have a neck with or without a lid, but with sealed walls and a bottom;

- closed completely sealed containers of the membrane type.

In the first case, everything is simple, the entire internal volume is filled with water and, if necessary, is drained through a pipe fixed at the lowest point.

In the case of membrane storage tanks, the useful volume is at least one third less than the volume of the entire structure. Part of the volume is diverted under the air chamber, separated from the water by a strong elastic membrane. As the container fills with water, the membrane presses on the air chamber, creating excess pressure. When it is required to receive water back, the valve opens, and it enters the water supply system under the action of the accumulated pressure.

Top or bottom

There are three options for connecting a storage tank and using the water supply:

- Top location of the container. In this case, the water intake is carried out under the influence of the force of gravity. The higher the accumulator is located in relation to the consumer, the stronger the water pressure. Every 10 meters of height add 0.1 atmosphere, or about 1 bar.

- Bottom location of a simple storage tank. Gravity will no longer help, and a pump is used to feed the water supply, which raises the pressure to the optimal level.

- Membrane storage tanks themselves create the required pressure for water supply. The lower location at the consumer level is optimal for them, since there will be no advantage from installation in the attic or tower.

How to determine the best option?

If a house has several floors and it is possible to arrange a storage tank in the attic, then this will allow you to do without additional installation pump, and you do not need to spend money on an expensive diaphragm tank. In fact, this is an analogue of a water tower. However, raise the container so high as to provide a comfortable head at the level of 2-2.5 atm. it's still difficult. Moreover, the question arises about the insulation of the tank, so that in winter period the water in it did not freeze.

In the event of an emergency shutdown of water, the available pressure is 0.2-0.3 atm. will be enough to use the mixer in the sink, toilet or even shower, but you will not be able to use some household appliances such as a washing machine or dishwasher, which require more pressure to operate the solenoid valves.

Installing the tank at a level with the consumer is suitable in cases where it is not possible to raise the tank to the attic or at least one floor higher. The same applies to the installation of a storage tank in an apartment. A small pump is required to supply water to the water supply under pressure. To ensure adequate operation, the pump will need a diaphragm expansion tank.

A storage tank with a membrane is perfect for storing a supply of water both when using a centralized water supply system and in an autonomous system. Moreover, it does not require additional equipment or overhead location. However, its cost is significantly higher than any conventional storage tank, even when combined with a simple pump.

Volume of the tank

![]()

In the event of problems on the city water supply line and water cutoffs, repair work is usually carried out in a day or two. However, accidents happen on holidays, and in places where quick repairs are simply impossible, then you will have to wait much longer. An optimal supply of water for 2-3 days will be based on using the toilet, maintaining personal hygiene and preparing food.

For a family of three, 100 liters per day is quite enough when using water in economy mode. One wash requires approximately 80 liters of water, more precisely, you can find out in the passport to washing machine... Likewise for the dishwasher.

It turns out that for 2-3 days when using household appliances, you need to look for a storage tank with a volume of at least 500 liters, half a cubic meter.

However, there are a number of limitations:

- The larger the volume of water and an open storage tank, the faster it will start to overgrow with sediment. It is not recommended to use containers with a volume of more than 200-250 liters in everyday life for long-term storage of water.

- Consideration should be given to the margin of safety of the floor and load-bearing walls. The installation of the tank must be laid even at the design stage of the house.

- When using autonomous water supply, the volume of the storage tank, especially of the membrane type, should not exceed the flow rate of the well. If this rule cannot be observed, then the pump must be protected from idle running.

The storage tanks of the membrane type are limited in their volume and are not able to give up the entire supply of the stored liquid. To form a stock of more than 300 liters, you will have to connect several tanks of smaller capacity in parallel to each other.

General connection rules

A water tank is installed on a prepared site: a concrete base tied with a foundation, or a reinforced metal frame made of a profiled pipe. The structure must withstand one and a half weight of the tank and water in it when fully filled.

The inlet pipe can be of any suitable diameter, the water is supplied under pressure. The outlet pipe and the pipe to the water supply are chosen with a diameter of one and a half to two times more than the section of the main line. Optimal size 32 mm.

Even the highest quality insulation only slows down the temperature drop in the tank. To prevent water from freezing, when installing the tank in an unheated attic or on the roof, use any suitable heating system for pipes and the storage tank itself.

With centralized water supply

Any type of storage tank connection requires check valve at the entrance to a house or apartment. It is the valve that will prevent the stored water from flowing back into the pipeline, and not to the consumer.

Top connection

The tank is installed under the ceiling of the first floor, on the floor above the bathroom and kitchen, or in the attic. The tank should have a nipple in the upper part for water supply, another slightly higher for discharge into the sewer in case of overflow and a nipple at the lowest part for water intake.

Already after the introduction of the coarse filter of the shut-off valve, meter and check valve, a tee is installed, from which the pipe goes to the inlet pipe of the tank, a shut-off valve or a controlled valve is installed in front of the connection.

A shut-off valve is connected to the outlet fitting and the pipe is lowered back to the water supply, with which it is connected through a tee.

The hose for dumping the surplus is lowered into the sewer or discharged outside the house into the front garden or drainage system.

To control the filling, a mechanical valve with a float is used, similar to those used in the toilet cistern.

To use the stored water, it is enough to open the outlet valve.

Bottom connection

The connection is performed in the same way as in the first option. However, a pump must be installed at the outlet to create additional pressure in the water supply. Before each use of water, you will have to turn on the pump first.

Ready-made will help to simplify life pumping station or supplementing the pump with a membrane-type expansion tank and a pressure switch.

Bottom connection of the storage tank with diaphragm

To connect the tank, only one pipe is used, connected to the water supply through a tee with a valve. The tie-in is carried out in the same way after the filter, meter and check valve.

The pressure in the air chamber must be adjusted before use. This must be done strictly in accordance with the instructions for the selected model. The normal pressure in the water supply system is preliminarily studied, moreover, taking into account fluctuations during the day. The average value is taken as a result, which is used to tune the tank. This is the only way to use the maximum useful volume of the tank.

For autonomous water supply

As in the case of a centralized water supply, there are several connection options.

Water tower

The storage tank is installed 15-20 meters above ground level in a fortified tower or attic. Water from borehole pump or a pumping station is fed directly into the tank, and from there it is distributed to the bathroom and to the kitchen in the house. The pressure in the system is provided by the height difference between the water level in the tank and the mixer tap in the house.

![]()

The disadvantage is the constant passage of water through the tank, which will cause sediment accumulation over time, even if a filter system is installed beforehand.

The advantage is in the simplicity of the design and the minimum of expensive elements, with the exception of the very structure of the tower and the obligatory insulation of the tank to protect it from freezing, even when it is placed in the attic.

Bottom connection of the storage tank

The tank is installed flush with the pumping station or on the ground floor in the house. It is filled during normal operation of the pump due to water from the well. The limiter is a float switch.

This option saves with excessive water consumption and a decrease in the water level in the well or well. However, it is useless when the electricity is turned off, since a pump is required to supply the end consumer with water from the supply.

Diaphragm storage tank

A membrane tank for storing the water supply is installed after the pumping station and the check valve, with a bottom connection. If the pumping station for some reason does not work and does not maintain the pressure in the system, then water comes from the storage tank.

A pond in the country is not only a beautiful element of garden design, but also a serious structure that will require some skills and abilities from the owner of the site to build it. At first glance, it seems that the process of creating an artificial reservoir can be simplified if you purchase a ready-made container. So it is or not, let's try to figure it out.

Features of creating a reservoir in the country

If natural reservoirs are formed by mother nature itself, then in any case significant efforts will be required when creating an artificial pond:

- you need to dig a pit, the shape of which will depend either on the contours of the tank, or on the planned "coastline" of an artificial reservoir;

- walls should be stepped and reinforced;

- when creating a pond, it is better to avoid strict, straight lines - this will make it look more natural. The finished containers are mainly made in the form of multilevel bowls with smooth, rounded outlines of irregular shape;

Advantages and disadvantages of a prefabricated pond

Artificial bowls have long been used in the construction of reservoirs on the site. They have many advantages.

- Availability- on sale there is a wide variety of any shapes, colors, and the containers themselves are made of different materials, from expensive and durable to cheap and light.

- Fast installation- the finished container is lowered into a pre-prepared pit, and then work follows on filling the pond with water and decorating it.

- Long service life- With proper care, plastic molds can last more than 20 years.

- Ease of installation- this is the easiest option for organizing a reservoir on a personal plot, it will require minimal effort.

- Simple operation- ready-made containers are easier to clean, and even there you can easily organize lighting or otherwise give the reservoir originality.

There are also drawbacks to ready-made containers.

- You cannot change the shape of the reservoir- if it is still theoretically possible to fill up a part of the pond, then it will not work to expand the static form.

- Dependence on weather factors- cheap plastic can crack in severe frost or become unusable in the bright sun, and in general due to temperature changes.

- Plastic is easier to damage during installation and during operation... Though modern forms quite durable, no one is immune from troubles.

- In similar containers harder to breed fish and plants.

- Price... Large containers are quite expensive, the same applies to molds for reservoirs from fiberglass or butyl rubber.

Advantages and disadvantages of a self-dug reservoir

It is not easy to build such a reservoir. But on the other hand, it has a lot of advantages.

- Can dig a pond of any shape and depth... There are no barriers for you, except, perhaps, the size of the site. Absolute creative freedom to create your own piece of design art.

- Creation costs pond from film lower than when buying a ready-made container.

- Film-based reservoirs also resistant to temperature extremes, sun and frost.

- Concrete ponds have absolute strength and reliability.

- It is possible to pick up non-toxic materials and keep in the reservoir living organisms.

When creating an artificial reservoir with your own hands, difficulties often arise. Here are the most typical ones.

- All work has to be done "from scratch"- to mark out the outlines of the future pond, dig a hole, strengthen the walls, decorate the pond and "revive" it.

- Materials and tools will need to be purchased separately. The worst thing is if by the beginning of construction you have nothing at all.

Reservoirs made of ready-made materials can have a wide variety of shapes:

- square;

- oval;

- rectangular;

- round;

- arbitrary.

Materials from which the finished forms are made:

- butyl rubber;

- plastic;

- fiberglass;

- cast iron or steel (if the basis of the pond is, for example, an old bathtub).

Ready-made plastic ponds

For the production of plastic reservoirs use polyethylene compressed under high pressure, or Pvc... Plastic basins can be of any length, width, depth, color and configuration. Volume artificial reservoirs from plastic ranges from 150 to 2500 liters.

They are installed in small areas and in cases where they do not want to pay special attention to the decor.

The main advantages reservoirs made of plastic are:

- lightness and strength;

- ease of installation;

- sufficient service life (10-15 years);

- unpretentious care.

Among disadvantages plastic containers, we note the following:

- cheap plastic cracks from the sun and frost;

- small volumes and the inability to expand the reservoir;

- high cost of quality containers;

- unnatural appearance.

Features of the installation of plastic reservoirs

The first step is to choose a suitable place where sunlight would only fall for a few hours a day. Otherwise, the pond will quickly "bloom". There should be no trees, bushes or other sources of additional debris nearby.

For a reliable installation of the finished reservoir, you need to perform a number of simple steps:

- Draw the outlines of the future pond on the soil. The easiest way is to turn the shape over and draw a circle around it;

- After that, remove the bowl and draw a line 20-25 cm from the one already drawn;

- Dig a hole along the contour of the second line and 20-30 cm more than the depth of the container;

- Remove roots and stones from the pit and compact the walls carefully;

- Fill the bottom of the pit with 20-30 cm sand (which we left "in reserve") and tamp it down. The edge of the form must be exactly at the ground level, and the base must be strictly horizontal. Use a level for accurate measurement;

- Fill the remaining space between the container and the pit walls with sand. Do this gradually, rinsing thoroughly with water every 20-30 cm of the layer;

- At the same time, start filling the container with water, as it is flexible and easily deformed. Continue the filling procedure until the bowl is stable and level in the pit;

- Fill your makeshift pond to the brim with fresh water and decorate it with rocks and other decorative elements.

Do not forget to periodically change the water in the plastic pond, as it is stagnant and begins to bloom quickly.

This video shows the simplest scheme for installing a pond from a ready-made form. Particular attention was paid to the choice of location, marking the contours, digging a pit and filling with water.

Differences between fiberglass reservoirs

Fiberglass containers come in a variety of sizes (up to 6,000 liters). Their distinctive features are:

- increased strength and ability to serve up to 30 years;

- environmentally friendly material, in such containers you can even breed fish;

- maintainability;

- immunity to UV radiation and resistance to severe frost.

The technology for installing fiberglass ponds does not differ from the installation of conventional plastic containers.

Bath pond

Baths, produced in Soviet times, were made of cast iron, a material that is resistant to high and low temperatures. Therefore, an old bathtub may well become the basis for your future pond. In addition to the fact that it will cost you completely free, it has several advantages:

- cast iron baths are very durable and last almost forever;

- the enamel of such a bath is durable and resistant to aggressive liquids, not to mention plain water;

- the cast-iron bath does not rattle when collecting water;

- turning it into a pond is easier than using any other option.

At the same time, using a bathtub as the base of a pond is not always preferable:

- it is quite problematic to transport a bathtub weighing 50-150 kg to the dacha;

- the enamel coating of the bathtub is very fragile, if you drop a heavy object, corrosion and destruction of the enamel will occur over time in the place where the crack appears;

- baths, as a rule, have the same rectangular shape, so the pond will not look entirely natural.

The subtleties of installing a bathtub as a reservoir

First of all, tightly seal the drain hole of the bathtub - you will no longer need it. The further algorithm of actions looks like this:

- dig a pit in the shape of the available container with a margin of 10-15 cm;

- lower the bath into the hole and use a level to determine that it is strictly horizontal;

- carefully fill the pit and carefully tamp the surface and seal the cracks;

- the inner sides must be treated with glue for ceramic tiles... Then you need to wait until the glue dries, covering the bathroom from moisture and debris;

- after the glue dries, lay a mesh-netting along the perimeter of the bathroom;

- then apply a cement-sand mixture to the mesh;

- the process ends with inlaid decorative stones, tiles or gravel.

The glue is applied in order to give the surface the natural color of the bottom of the reservoir, so it is even good if it is applied in an uneven layer.

Film backed pond

Among the reservoirs that are built with their own hands, the first in popularity is the film-based pond. His Benefits obvious:

- thanks to the film "bottom" the reservoir can be given absolutely any shape and depth;

- over time, the outline of the reservoir can be corrected;

- the material is subject to restoration and restoration, damage is repaired without special costs;

- the film is frost-resistant.

However, film reservoirs also have limitations:

- the film is easy to damage (cut, tear) during cleaning and installation;

- the edges of the film that lie on the surface can "melt" from the hot sun;

- folded film bottom requires additional "masking";

- if a large reservoir is conceived, then the film will have to be glued in several places.

Secrets of making a film pond

With the right approach, a film reservoir can last more than 10 years. In addition to the film itself, shovels and tools for marking, you will need geotextiles or felt, means for repairing the film and some artificial materials for the "coastal" zone. The process of creating a film pond consists of seven easy steps.

- First of all, mark the contours of the future reservoir on the ground, giving it any shape and depth.

- When digging a pit, alternate ledges and "rapids" - this gives the banks strength, the earth will not crumble. The width of the “threshold” is about 30 cm, the slope is 45-50 degrees.

- Dig a pit 15-20 cm deeper than the estimated depth of the reservoir - this stock is needed to tamp crushed stone (5 cm layer) and sand (10 cm).

- Clean the bottom of roots and stones and cover with geotextiles or special felt. Continuously tamp the bottom.

- Leave the film in direct sunlight for 2 hours and start to overlap the bottom with it. It is desirable that the foundation pit be covered with a single piece of film. If the whole piece is not enough, glue the individual pieces with special PVC film glue.

- Spread the plastic out as evenly as possible. Fill the pond with water by a third, after 2-3 hours - by another third, and after another 3 hours, completely fill the pond with water. This is necessary so that the film gradually stretches under the weight of the water.

- Cut off the extra pieces of film around the edges and start decorating - lay stones along the coastline, let the flora and fauna in and enjoy the beautiful view.

The video shows the steps for creating and strengthening a simple film-based pond.

Concrete pond

A concrete pond belongs to the category of structures that are built "for centuries". This is due to a number of reasons:

- concrete has incredible strength and durability;

- the reservoir can be given any shape;

- the concrete pond is easy to maintain;

- concrete structures are compatible with any engineering equipment;

- low cost of cement.

However, concrete ponds have certain limitations:

- it is quite difficult to build a concrete bowl;

- additional processing is needed with a frost-resistant agent and liquid glass;

Algorithm for building a concrete pond

If you are ready to surprise the world with a buried concrete pool, then preparatory work should look like this:

- dig a pit with a margin of 20-25 cm necessary to compact the bottom (make the pit walls with a slope of 20-30 degrees);

- do not forget to make ledges (thresholds) to enhance the strength of the structure;

- remove the remnants of roots and small stones;

- cover the bottom with rubble with a layer of 15 cm and tamp;

- Lay the waterproofing layer starting from the center of the pit towards the surface of the ground.

- knead the composition in a ratio of 3: 1 (three parts of sand to one part of cement);

- the amount should be enough to completely fill the pit in at least one layer (6-7 cm thick);

- make a mesh of wire and reinforcement with a mesh diameter (7-10 cm);

- press the mesh into uncured concrete so that its edges protrude slightly above the coating;

- after the concrete layer, reinforced with reinforcement, has dried, prepare a new mortar;

- moisten the walls of the pit with water and fill in the second layer of concrete 5-6 cm thick;

- align the bottom and sides of the concrete bowl;

- let the concrete harden, and then apply a layer of water glass.

As you can see, each type of water body has its own advantages and disadvantages. Which one to choose is up to you.

specials.usadbaonline.ru

Advantages and disadvantages

There are many advantages of such a pit (or a septic tank for the sewage system), and all of them are of great importance for the profitability and safety of the sewage system.

A plastic container is:

- absolute tightness;

- safety for nature and humans (the soil remains clean);

- power independence;

- the ability to choose any volume convenient for the owners;

- light weight - the workpiece for the septic tank can be lifted and installed without any problems;

- material resistance to aggressive media and corrosion;

- ease of installation (it is easy to saw through the walls of the tank to connect pipes);

low cost.

The disadvantages of the owners include:

- the likelihood of a tank floating up during periods of spring floods;

- danger of crushing, deformation and cracking in winter when the soil is frozen:

- the need for regular sewage disposal;

- the appearance of an unpleasant odor - waste decomposes in the process of natural decay.

However, with a reasonable approach and care in operation, the owners can avoid any troubles with the plastic container. In fact, the advantages of plastic cover all its possible disadvantages. This is a cheap and fairly practical structure that helps to solve the problem with sewage waste.

What to choose?

It is quite simple to decide on the choice of a suitable container made of plastic or polymers. The main selection parameters are working volume and strength.

For a family of three or four, a container with a capacity of 2,500-3,000 liters is sufficient. It will allow you not only to wash dishes and take a shower, but also to install a washing machine, dishwasher, bath.

For a family of three or four, a container with a capacity of 2,500-3,000 liters is sufficient. It will allow you not only to wash dishes and take a shower, but also to install a washing machine, dishwasher, bath.

As for strength, preference should be given to products with a wall and bottom thickness of at least 1.2-1.5 centimeters. The safety factor will allow the tank to resist soil pressure. And enough weight will keep it in the soil. True, for greater reliability, it is still better to additionally strengthen the capacity.

For the needs of the owners, two options are suitable.

Plastic barrels

Ordinary plastic drums with a capacity of 200 liters. To increase the working volume, two or three barrels must be connected in series using overflow pipes. The total volume of sewage must be three times less than the working volume of these storage wells! On average, one person consumes 200-400 liters of water per day.

Eurocubes

For large families and cottages the best choice will become a Eurocube. Can now be found  used containers of this type and purchase them at a completely affordable price. Sectional storage septic tanks are also assembled from eurocubes. Resourceful owners complicate the design by adding a compressor and aerator. The result is complete sewage treatment plant at a budget price, but with good functionality and efficiency. The main advantage of any Eurocube is its shape and sufficient capacity. Rectangular corners allow owners to save money on earthwork. Indeed, when installing barrels or tanks, you have to remove "excess" soil in large volumes.

used containers of this type and purchase them at a completely affordable price. Sectional storage septic tanks are also assembled from eurocubes. Resourceful owners complicate the design by adding a compressor and aerator. The result is complete sewage treatment plant at a budget price, but with good functionality and efficiency. The main advantage of any Eurocube is its shape and sufficient capacity. Rectangular corners allow owners to save money on earthwork. Indeed, when installing barrels or tanks, you have to remove "excess" soil in large volumes.

Principle of operation

Any plastic container functions simply. Waste accumulates in it and gradually settles. In the sludge settled on the bottom, natural rotting processes begin - anaerobic bacteria begin to work. As a result, a characteristic smell appears near the sewer drain - this is one of the obvious disadvantages of such a system.

Any plastic container functions simply. Waste accumulates in it and gradually settles. In the sludge settled on the bottom, natural rotting processes begin - anaerobic bacteria begin to work. As a result, a characteristic smell appears near the sewer drain - this is one of the obvious disadvantages of such a system.

As it fills, the liquid and bottom sludge are pumped out using sewage equipment. To save on calling specialists, you can install a structure with several sections that allow the water to settle several times and to be purified as much as possible. From the last container, the liquid flows out by gravity onto the filtration field or into a filter well with a reliable natural filter at the bottom (sand, crushed stone, peat, etc.).

Filtration into the ground is prohibited if there are harmful chemical impurities or fecal matter in the effluent. The ingress of hazardous substances into the soil can provoke infectious diseases or poisoning in the residents of the house.

Construction device

The containers are placed in the pit in steps - the first is always higher than the next. That  the same principle applies to overflow pipes. The inlet pipe is 20 centimeters higher than the outgoing pipe. This design provides a high-quality movement of fluids by gravity. The liquid that got into the sewer naturally fills the first container, and then pours into the second, and so on.

the same principle applies to overflow pipes. The inlet pipe is 20 centimeters higher than the outgoing pipe. This design provides a high-quality movement of fluids by gravity. The liquid that got into the sewer naturally fills the first container, and then pours into the second, and so on.

The containers are installed on a sand cushion with a thickness of at least 20 centimeters. The installation uses a backfill with a mixture of sand and cement. Above is a ceiling with hatches and ventilation pipes (for each separate section with a diameter of 11 centimeters).

How to choose materials?

When choosing building material it is necessary first of all to pay attention to its quality.

The container should be solid, not have chips or cracks. The optimal wall thickness is from 1.2 centimeters. But the main focus is, of course, on calculating the working volume. So for a family of three, you can install three Eurocubes with a total capacity of 3,000 liters. Three cubic meters of volume will make the life of the owners as comfortable as possible.

It is allowed to use used containers without signs of wear.

Their purchase will save the family budget.

How to install?

To carry out installation work, a minimum of tools are required:

- shovel and bayonet shovel;

- grinder and drill for making technical holes.

The list of basic components and materials is much wider. You will need:

- glue suitable for working with plastic;

- sealant;

- clamps for connecting pipes;

- sand and cement;

- cables for fastening containers;

- the containers themselves;

- flanges and couplings;

- plastic pipes (diameter 11 cm);

- pipes for arranging ventilation (sewer pipes may also be suitable).

Installation work includes the following stages:

- The containers are being prepared. Holes for pipes are cut. The inlet is located 20 cm from the top edge, and the outlet is 40 centimeters - this provides the height difference necessary for correct operation. Openings for ventilation pipes are also prepared.

- A pit of suitable dimensions is dug. Sand is poured at its bottom. If additional fastening of containers is planned, the bottom is poured with concrete. Simultaneously installed metal hinges for fastening cables.

- The containers are lowered into the prepared foundation pit and fixed to the bottom. Pipes are connected and ventilation is installed. All joints are carefully treated with a sealant.

- Backfilling is in progress. Sand can be used, but it is better to backfill with a mixture of sand and cement (ratio of five to one). The containers must be partially filled with water in order to equalize the external pressure from the soil side!

- The roof of the building is insulated with mineral wool, which will ensure uninterrupted operation of the sewage system in the cold season.

Typical mistakes when performing installation work is:

- no slope of pipes towards septic tanks;

- the presence of multiple bends and turns, which increases the risk of clogging the system.

The price of the issue

Eurocubes are widely used in industry for the transportation of various liquids. Therefore, used products can be purchased at a price of only 3,000-5,000 rubles. There are also cheaper options. At such a budget price, the owners will receive spacious and durable containers with a reliable frame made of galvanized steel.

Installation of a unit consisting of several Eurocubes is quite simple. If for some reason the owners cannot cope with the task on their own, you can turn to specialists for help. Installation work usually includes excavation, installation and connection. It will cost about a third of the cost of Eurocubes (from 5,000 rubles, depending on the region).

Correct operation

Homemade septic tanks also need regular inspection and maintenance, as well as industrial models of sewage treatment plants.

Repair work may be necessary in the event of a clogged sewer. You will need to clean the overflow and sewer pipes... For such work, it is better to involve a professional plumber. To avoid clogging problems, it is necessary to periodically add to storage tank biological preparations containing special cultures of bacteria, which are able to break down fat plugs and deposits.

Maintenance includes:

- Regular pumping out of the contents of the container. The frequency depends on the intensity of use sewer system and the volume of septic tanks. Usually it is from one to three pumpings per year with the involvement of special equipment.

- Insulation of the lid in the cold season, which accelerates the processes of decay and wastewater treatment.

- And, of course, you must comply with the most simple rules- do not throw large mechanical waste and hygiene items into the sewer.

greenologia.ru

DIY rainwater cisterns

“Fresh water is very important element food, about 150 liters per person are consumed every day in Germany, of which only 3 liters is spent on cooking.

Yes, water is (yet) relatively cheap. We have 1000 liters of tap water cost about 6 euros, including the cost of sewerage. And now the first problem is obvious! When I water my garden with tap water, I have no drains at all, for which I, however, have to pay! Another socially created problem is that I have to pay for storm water from my site, even though I don't use it.

But what if you try to collect rainwater in a special reservoir and water the garden with it, and also use it for cleaning, flushing the toilet or even washing, while saving high-quality tap water? Plus, rainwater has its own benefits:

- It is better for washing

- Does not form limescale in the washing machine

- Better tolerated by plants, etc.

Cisterns for collecting rainwater are sold in construction markets, but the smallest of them (1,500 liters) costs 2,000 euros. It is so expensive that it will never pay for the work done. Barrels for water can be bought much cheaper. But in the hot season, the water in them quickly deteriorates, begins to smell disgusting, and all kinds of insects start up in it. It is also not suitable for an underground reservoir. In mine, the temperature, starting in the middle of summer, like in winter, fluctuates in the range of 5-10 degrees above zero.

Whoever has hands growing out of the right place and who is not afraid of physical work, he may well build such a tank on his own and quite cheaply. Here is my progress report.

Experience in operating a tank for a septic tank

My tank survived 14 days of cold with a temperature of -20 ° C without any problems, although the water almost reached the hatch. The ice was about 15 cm thick.

More than 5 years have passed since the start of construction, and at the time of 2013 has not yet noticed a single damage.

- Water intake in 2008 - 4000 liters

- Water intake in 2009 - 7000 liters

- Water withdrawal in 2010 - 8000 liters (Construction costs paid off)

- Water intake in 2011 - 8000 liters

- Water intake in 2012 - 5400 liters

- Water intake in 2013 - 1000 liters

Water tank. Instruction with pictures

Construction began in September 2007.

In mid-October 2007, I was already at a depth of 2.20 m in a pit 1.40 m in diameter.

At this depth, I poured concrete 10 cm thick. For the walls, I took a 100x25x5 cm concrete curb for 1.40 euros / piece from a nearby construction market. Of these, I laid out a circular wall 15 stones high right on the concrete pad. It was in the first week of November, then my construction site slowed down due to weather conditions. In April 2008, construction continued. The pit lined with a stone was 120 cm in inner diameter and 130 cm in outer diameter. Its height was 201 cm. At the end, I cleaned out the grooves between the stones using the same concrete.

The inner surface, including the base, I treated with a hydro-binding sealing solution to prevent water seepage. This solution is diluted with water and becomes similar to a yoghurt mass, which is very convenient to apply with a regular wallpaper brush. I left each layer for a day to dry completely. 5-6 layers is usually enough, in any case you can always process the inner surface again.

I made small holes between the hatch and the wall. I did not process this transition with a hydraulic solution, it remained permeable. This is enough. At least I've never had a flood yet.

Hydraulic solution (25 kg bags in construction markets) is a cement-synthetic mixture that serves to protect surfaces from water penetration (as well as from water loss from the inside). The hydro solution fills all the pores and is applied several times after the first layer has dried.

I filled the space behind the curb with rubble and concrete.

At the height of the top three rows of stones, I made several holes - two for the filling pipes and one for the pump pipe.

The tank is open. The hatch is large enough to accommodate a ladder.

I made the hatch cover in my own garden. I dug a hole 10 cm deep and 140 cm in diameter, installed an old zinc bath there upside down and poured a concrete area around it. But first, I put a film on the ground. When the concrete hardened, I removed the bathtub, put a film in its place and poured concrete up to the top edge. Now I have a top hatch cover. To make it easier to lift such a cover (50 kg), I mounted two handles in it.

Both covers, as well as the base of the tank, later had to be reinforced with steel.

The tank is closed here. Both lids close tightly to keep out dirt, animals and children. To make the design look prettier, you can scatter rubble around. On the left and right of the building, you can see pipes for collecting rainwater.

In the lower third of the pipes, I installed homemade filter for coarse dirt.

The filter is, of course, very simple, but effective. It consists of a funnel-shaped PVC pipe that simply slides into the collection pipe and a round tea strainer. Cleaning this filter takes only 10 seconds.

To pump out the water, I installed a special pump. I already had the hose. For the pump, I built a separate booth without any frills. It is in it that he serves me faithfully, protected from wind and bad weather.

The top cover can only be opened when the door is open.

Which is locked with a key.

Outcomes

The volume of my cistern is 2300 liters, which is enough for a whole garden.

The pH of the water is 7.1, it does not contain nitrates at all.

Four-stage filtration system

- In the gutter

- In rainwater collection pipes

- In the hose

- Built-in filter in the pump

This tank must be cleaned every 5-10 years. After about 3 months, a silty sediment, the so-called sediment, forms at the bottom. This layer is made up of "good" bacteria that purify the water.

It is therefore very important that the pump hose does not touch the bottom of the tank.

The construction time was about 300 hours, the cost without a pump was about 100 euros. I believe that cheaper and better is simply not possible. Even if I am just a dilettante. "

We hope that this guide to action will help you make your site more comfortable and cost-effective.

On our website, the topic of water in the country was raised quite often. The fact that water is the source of life is not so much a beautiful phrase or metaphor as a harsh reality, everyone who, in the summer heat, finds himself without water in the central water supply system (if such a one was made in the country at all) will have to make sure. Neither wash nor water the garden - and indeed nothing can be done without water.

On our website, the topic of water in the country was raised quite often. The fact that water is the source of life is not so much a beautiful phrase or metaphor as a harsh reality, everyone who, in the summer heat, finds himself without water in the central water supply system (if such a one was made in the country at all) will have to make sure. Neither wash nor water the garden - and indeed nothing can be done without water.

Before you is one of the options that allows you to get out of this situation. A water tank raised by the author to a height under natural pressure will supply you with water in the event of such force majeure situations. For those who could not find water on the site, build a well, or make, for example, a well for some reason, a water tank mounted at a height with their own hands, this is the simplest and cheapest solution in financial terms. For example, it can be easily applied for DIY construction at the summer cottage (for more details, follow the link).

We use the dacha only in the summer (from April to September), so we placed the reserve water tank outside the house. The obvious advantages of such a solution include the absence of additional loads on building structures, as well as an almost complete guarantee against leaks and flooding of premises in any emergency with a storage tank. The only thing I would like to make a reservation about right away is that we do not use water from the main water supply for drinking due to the high content of iron in it (brown water).

We took a plastic barrel with a volume of about 190 liters as a water storage tank. It used to serve as a storage container for concentrated pineapple juice. This choice was dictated by the fact that plastic barrel much lighter than a metal tank and does not need additional corrosion protection. Serious modifications to the water supply barrel were also not required. I only had to cut out the upper bottom, since the hatch in it was too small and inconvenient.

To install a barrel for water outside the building, we had to make a so-called overpass, on the upper platform of which we installed a water tank with our own hands. The material for the construction of the overpass was water pipes with a cross section of 50 mm. Threaded plumbing couplings, tees and elbows were used to connect the structural elements. The height of the overpass is about 3 m. A ladder was mounted on the back side of the overpass to rise to its upper platform. The rungs of the stairs are made of steel plates that are bolted to the uprights with nuts.

After assembling the overpass, the tank was connected to the main pipeline, which runs in the ground next to the overpass. To do this, a valve was installed at the outlet from the pipeline at ground level, from which pipes with a cross section of 15 mm were launched upward and introduced into the upper part of the tank. At a distance of about 1.5 m from the valve, shower branches were made.

A float valve from the toilet cistern was installed on the pipe of the upper part of the tank. The valve allows you to automatically fill the tank to the maximum level and always have the necessary supply of water. To prevent leaves and other debris from getting into the pressure tank, we cover it with a round metal lid on top.

Water was injected into the house directly from a pressure storage tank. To do this, a hole was drilled in the lower part of the tank, a pipe with a section of 15 mm was extended from it towards the house and brought inside through a hole in the upper part of the wall. All pipe connections are threaded. In the house, the pipe was extended to the water tap in the kitchen.

To drain the water for the winter, a hole was drilled in the bottom of the barrel, into which a short pipe with a stopcock was inserted. To quickly empty the pressure container, simply open the tap and drain off all the water.

To collect contaminated wastewater, a septic filtering well with a depth of 2 and a diameter of 1.5 meters was made right under the overpass in the ground. Since we only need to tap household Wastewater that do not contain feces, then such the simplest scheme water treatment is completely justified and completely safe from an environmental point of view.

Below are other entries on the topic "How to do it yourself - for a householder!"

Subscribe to updates in our groups.